Stainless Steel Pipe Fittings

EATHU Stainless Steel Slip On Flange

Application:

SLIP ON PIPE FLANGE is also called SO flange,it is suitable for the connection of carbon steel pipes with a nominal pressure of no more than 2.5MPa. Slip on flange mostly used for when the medium conditions are relatively mild, such as low-pressure non-purified compressed air and low-pressure circulating water. SLIP-ON FLANGES place two fillets by welding, sliding inside the tube. So its installation cost is lower, requiring less precision in cutting the pipe.

Specification:

PRODUCT NAME | Stainless Steel Slip On Flange |

SAMPLE SUPPORT | Yes |

DELIVERY TIME | Depends on Quantity and Other Requirements |

MOQ | 200kg / Depends on Flange Size |

PRICE | The Higher The Quantity, The Cheaper |

SIZE | 1/2"-60"(DN10-DN1500) |

MATERIAL | Carbon steel / ASTM Alloy Steel / Stainless steel |

THICKNESS | View Flange Catalog |

PRESSURE RATING: | View Flange Catalog |

SEALING SURFACE | FF, RF, MFM, TG, FF |

SURFACE TREATMENT: | Anti-rust oil / Raw. |

CERTIFICATION | ISO9001:2000 , API, CE, According to Requirements |

Product Details

Stainless Steel Slip-on Flange Applications

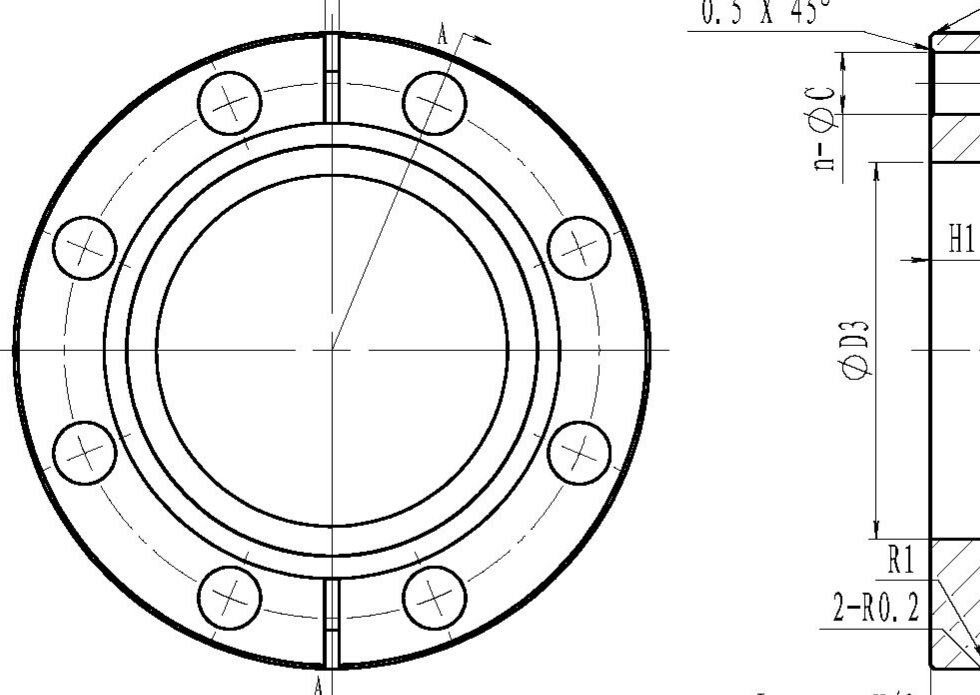

Stainless steel slip on flanges typically have a raised or flat face. If a raised face is required for a spigot flange, the standard raised face height is 1/16″ for spigot flanges up to 400#. For 400# and above, the standard raised face height of the slip-on pipe flange is 1/4″.

Slip-on flanges are commonly used in the following applications:

Low Pressure Applications: Slip-on flanges are widely used in low pressure applications where pressures do not exceed 300 psi, such as water and gas pipelines.

Chemical and Petrochemical Plants: Commonly found in chemical and petrochemical plants, slip-on flanges are used to connect piping systems and equipment.

HVAC Systems: Slip-on flanges are commonly used in HVAC (Heating, Ventilation and Air Conditioning) systems to connect piping systems and ducts.

Water Treatment Plants: Slip-on flanges are commonly used in water treatment plants to connect pipework and equipment.

Food and Beverage Industry: Slip-on flanges are widely used in the food and beverage industry to connect piping systems and equipment.

Stainless steel slip-on flanges are ideal for process lines that help regulate the flow of steam, oil, gas, and other fluids. They are best applied in low-pressure, high-temperature systems.

Benefits of EATHU Forged Flange Factory

EATHU is a professional flange forging factory in China for thirty years., dedicated to producing and supplying high-quality flange products. Our continuous technological innovation and quality management have earned us a good reputation and customer base. We have three flange production lines and one stainless steel flange production line, which can meet the flange needs of different materials and specifications.

EATHU forging factory possesses advanced production equipment, such as CNC lathes, CNC machining centers, and forging equipment.

Our factory is equipped with advanced production equipment and technology, as well as a strict quality control system. Our production process is in line with international standards, ensuring stable and reliable product quality. Whether it is plate flanges, butt-welding flanges, threaded flanges or other types of flanges, we are able to meet the different needs of our customers.

|  |

|

EATHU Offers High Quality Flanges

EATHU always puts the quality of stainless steel slip-on flanges in the first place, because of our quality management and persistence, we have obtained ISO9001 certification, which is officially certified, and we have also won the trust of our customers.

EATHU always puts the quality of stainless steel slip-on flanges in the first place, because of our quality management and persistence, we have obtained ISO9001 certification, which is officially certified, and we have also won the trust of our customers.

EATHU has a professional quality management team, from raw material purchasing to product production, processing, packaging, transport, each process is strictly quality management, to ensure compliance with ISO9001 standards, in raw materials, we have a fixed supplier of raw materials, in the production process, we use advanced forging production equipment, to provide a strong guarantee for the manufacture of flanges, fittings and other products, in the Before shipment, our quality management team will also carry out strict product testing to ensure that customers receive the most satisfactory products.

We strictly adhere to the principle of ''100% testing during production and 100% inspection before delivery''.

EATHU Has the Most Professional Technical Team

Our technical team consists of a group of experienced engineers and technical experts with deep expertise in flange design, manufacturing and application. Not only are they familiar with the latest technologies and processes, they also have the ability to solve complex problems and tailor solutions for customers.

Our technical team focuses on innovation and continuous learning, and constantly pursues technological progress and improvement. They work closely with customers to understand their needs and challenges, provide customers with customized solutions, and ensure that product quality and performance are at optimal levels.

Whether in the product design stage, production process or after-sales service, our technical team will wholeheartedly provide support and assistance to customers to ensure the highest level of customer satisfaction. We believe that through the expertise and services of our technical team, we can create greater value and a better experience for our customers.

EATHU Supports Customised Flange

As a professional flange factory, we provide customers with customized production services to meet their specific needs and requirements. The following is an introduction to our customized production services:

Personalized design: Our engineering team can carry out personalized design according to the specific requirements of customers, including flange products of different materials, specifications, sizes and standards. We will work closely with customers to understand their needs and provide professional design solutions.

Customized production: We have advanced production equipment and technology and can carry out customized production according to customers' design requirements. Whether plate flanges, butt weld flanges, threaded flanges or other types of flanges, we can meet our customers' specific needs.

Quality Assurance: We strictly implement quality control standards to ensure the quality of customized products is stable and reliable. We will provide customers with high-quality products that meet international standards to meet their quality requirements.

Flexible production capacity: We have flexible production capacity and can reasonably arrange production plans according to customer order requirements to ensure timely delivery of customized products required by customers.

Professional technical support: Our technical team will provide customers with professional technical support, including product selection, engineering design, production technology and other issues. We will provide personalized solutions based on our customers' specific needs.

In short, we will provide customers with all-round support with high-quality products, professional services and flexible customization capabilities. We look forward to cooperating with you and developing together.

inquire now

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.