304 Stainless Steel Flange Depth Analysis: Material & Application

In the modern engineering field, flanges are important components for connecting pipelines and equipment, and 304 stainless steel flanges stand out among numerous flange types with their unique advantages.

I. Flange Material Characteristics

The outstanding performance of 304 stainless steel flanges first stems from their material. 304 stainless steel contains 8 - 10.5% nickel and 18 - 20% chromium. The chromium element plays a vital role in it, as it can form a dense chromium oxide protective film on the surface of the stainless steel. This film is like a barrier, effectively preventing external substances such as oxygen, water, acid and alkali substances from contacting the internal matrix of the stainless steel, thus endowing 304 stainless steel with antioxidant properties.

The addition of nickel further enhances the corrosion resistance of the stainless steel. In different corrosive environments (such as chloride environments), nickel can improve the internal structure of steel, enabling 304 stainless steel to resist the erosion of various chemical substances. For example, in marine environments or environments with chemical media containing chloride ions, many common steel materials are prone to corrosion and rusting, but 304 stainless steel flanges can still maintain good appearance and performance.

In addition to corrosion resistance, 304 stainless steel flanges also exhibit satisfactory mechanical properties. They have relatively high strength and can withstand a certain degree of external forces without deformation or damage. This enables them to perform well under conditions such as internal pipeline pressure, tension and external mechanical impacts.

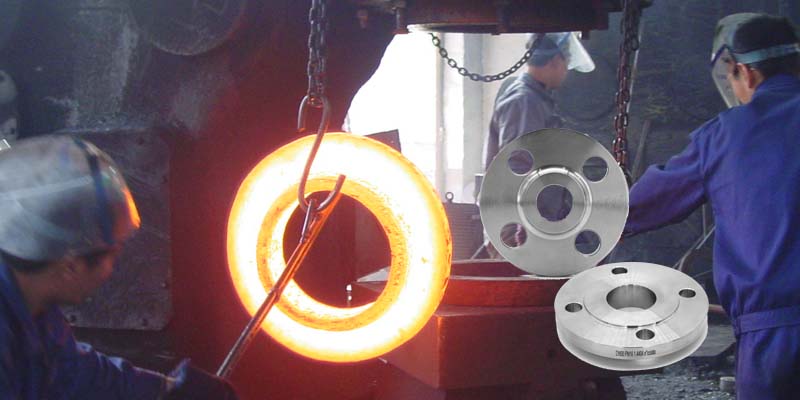

The processing performance of 304 stainless steel flanges is also excellent. Whether it is forging, stamping, turning or milling and other processing techniques, they can all be carried out smoothly. This characteristic allows manufacturers to easily process raw materials into flange products of various shapes and specifications according to different design requirements. For example, when manufacturing small and precise pipeline connection flanges, precise turning processing can be carried out; while in the production of large chemical pipeline flanges, the stamping process can efficiently produce products that meet the size requirements.

The welding performance is also an important advantage of 304 stainless steel flanges. It can cooperate well with multiple welding processes (such as argon arc welding), and the strength and tightness of the welded joints can be reliably guaranteed. This makes it convenient and fast to connect various pipe fittings and equipment through flanges during the pipeline installation on the engineering site to form a complete system.

II. Flange Application Fields

The application fields of 304 stainless steel flanges are extremely extensive.

The chemical industry is one of the important application scenarios of 304 stainless steel flanges. During the chemical production process, a large amount of chemical raw materials and products need to be transported in pipelines, and these pipelines often face complex medium compositions, high pressure and high temperature. 304 stainless steel flanges can stably withstand these harsh conditions for a long time. For example, in sulfuric acid production plants, sulfuric acid is highly corrosive, and ordinary carbon steel flanges will be corroded and penetrated in a short time, while 304 stainless steel flanges can stay in service for a long time, ensuring the sealing and safety of the pipeline connection parts and effectively preventing sulfuric acid leakage, which is of irreplaceable significance for ensuring the safety of chemical production and environmental safety.

The petroleum industry also cannot do without 304 stainless steel flanges. From oil exploration to transportation and then to refining, there are requirements for the quality of flanges in every link. On offshore oil exploration platforms, equipment faces the dual challenges of seawater immersion, high humidity, high salinity and the corrosion of various chemical substances contained in petroleum products. The corrosion resistance of 304 stainless steel flanges makes them an ideal choice for connecting oil and gas pipelines, oil production equipment and various auxiliary equipment.

In the power industry, many power plants need to use corrosion-resistant flanges in links such as the cooling water circulation system. For example, thermal power plants use a large amount of water for cooling, and the cooling water may contain various minerals and impurities and has a certain degree of corrosiveness. The use of 304 stainless steel flanges can ensure the tightness of the cooling water pipelines and improve the reliability and stability of the entire power generation system.

The paper industry involves the transportation of pulp during the production process. The pulp contains plant fibers, chemical agents and other components, which pose risks of corrosion and blockage to the flanges for pipeline connection. 304 stainless steel flanges can resist the erosion of such complex media, and their smooth surfaces are not easy to attach impurities, which is convenient for cleaning and maintenance and helps to ensure the continuous operation of the paper production line.

The food industry has extremely high requirements for hygiene and safety. Due to its safe and hygienic characteristics, 304 stainless steel flanges are widely used in the pipeline connections between food processing equipment. Whether it is in the production and processing of fruit juice, milk or the connection of meat processing equipment, 304 stainless steel flanges will not release harmful substances and can effectively prevent external pollution from entering the pipeline system, ensuring the quality and safety of food.

III. Selection Tips

When selecting 304 stainless steel flanges, multiple factors need to be comprehensively considered.

The corrosiveness of the working environment is one of the most critical factors. If the working environment belongs to a strongly oxidizing environment, such as the existence of high-concentration nitric acid or high-temperature concentrated sulfuric acid, although 304 stainless steel has a certain degree of corrosion resistance, it may still be necessary to further evaluate whether it is necessary to adopt more professional corrosion-resistant flanges or take additional protective measures. In a mildly corrosive environment, such as the general domestic sewage pipeline system, 304 stainless steel flanges may be sufficient to meet the requirements.

The pressure requirement must also be emphasized. In different engineering application scenarios, the internal pressure of pipelines varies greatly. For example, in urban tap water pipe networks, the pressure is relatively low; while in oil and gas transmission pipelines, the pressure may be very high. Therefore, it is necessary to select flanges with appropriate strength grades according to the actual working pressure, and ensure that accessories such as flange gaskets can also withstand the corresponding pressure.

The temperature range is another important consideration factor. If the working temperature is too high, the performance of 304 stainless steel may change to some extent in a high-temperature environment, such as a decrease in strength; while in a low-temperature environment, although the performance of 304 stainless steel is relatively stable, it is also necessary to consider the compatibility with other components such as sealing materials at low temperatures.

Safety cannot be ignored either. In pipeline systems involving dangerous media (such as toxic gases, flammable and explosive liquids), it is necessary to select 304 stainless steel flanges that are reliable in quality and have passed strict inspections, and ensure the tightness of the flange connections to prevent medium leakage and safety accidents.

At the same time, attention should be paid to the connection methods of flanges. Common connection methods include threaded connection, welded connection and flange connection (bolted connection). Different connection methods are suitable for different working conditions. Threaded connection is suitable for small-diameter pipelines and requires high precision at the pipeline connection parts; welded connection is suitable for pipelines that need permanent connection and has good sealing performance; while flange connection has a certain degree of detachability and is widely used in occasions where pipelines need to be maintained or replaced frequently.

The specification and size should be selected according to the specific size of the pipeline. Ensure that the inner diameter, outer diameter, thickness and other dimensional parameters of the flange match the pipeline, and consider parameters such as the nominal diameter and working pressure of the pipeline to select appropriate standard flanges.

The processing precision will also affect the performance of the flange. Flanges with high processing precision can better ensure the tightness and strength of the connection during installation and use. Therefore, when selecting flanges, it is advisable to give priority to manufacturers with advanced processing techniques and strict quality control.

In addition, attention should also be paid to the compatibility with flanges of other materials. In a complex pipeline system, there may be pipe fittings and flanges of multiple materials. If the compatibility between different materials is poor, problems such as electrochemical corrosion are likely to occur. For example, in a pipeline system with both 304 stainless steel flanges and carbon steel flanges, appropriate measures (such as coating with organic coatings) should be taken to prevent corrosion between them.

|

|

|

IV. Summary and Suggestions-EATHU FLANGE FACTORY

In summary, 304 stainless steel flanges, with their excellent material characteristics, have shown strong adaptability and reliability in multiple industries such as chemical, petroleum, power, paper and food. Their advantages in corrosion resistance, mechanical properties, processing performance and welding performance make them an important option for flange selection in the engineering field.

In engineering design and actual enterprise applications, selecting 304 stainless steel flanges is not a simple material selection process, but a systematic project that requires comprehensive consideration of numerous factors. It is necessary to conduct a comprehensive and detailed assessment according to the actual requirements of the working environment, pressure, temperature, safety and other aspects, combined with factors such as the connection method, specification and size, processing precision and compatibility with other materials of the flanges.

Only in this way can the most suitable 304 stainless steel flange products be selected, thus ensuring the stability and safety of the engineering system, improving the operation efficiency of the entire system, prolonging the service life of related equipment, saving costs for enterprises and bringing long-term economic benefits. With the continuous development of technology, there will be more possibilities for the performance optimization and application expansion of 304 stainless steel flanges in the future. We should continue to pay attention and make wise choices according to actual needs.

The Outstanding Capabilities of EATHU in the Flange Industry

In the global flange industry, EATHU has become a trusted brand by customers with its all-round advantages and continues to drive the progress and development of the industry.

Advanced Technology for Precise Manufacturing

EATHU has always kept up with the technological forefront and made significant investments in research and development as well as the introduction of advanced manufacturing processes. During forging, high-precision die forging technology is employed to distribute the metal fiber flow lines of flanges reasonably, enhancing the strength and toughness of the products and ensuring that they can withstand high pressure and complex working conditions. In mechanical processing, advanced CNC machining equipment is utilized, with a machining accuracy reaching ±0.01mm, strictly guaranteeing the dimensional precision and meeting the high-precision requirements for flanges of various specifications.

Stringent Standards for Quality Control

Quality is at the core of EATHU. The enterprise has established a comprehensive and strict quality control system. Starting from the procurement of raw materials, each batch of steel is subjected to composition analysis and performance testing to ensure that it complies with the standards of stainless steel materials such as 304 and 316L. Multiple quality inspection checkpoints are set up during the production process, and advanced non-destructive testing equipment is used for flaw detection to promptly identify and eliminate any potential internal defects. Before the finished products leave the factory, comprehensive inspections are carried out on the flatness of the sealing surfaces, the spacing of bolt holes, etc. in accordance with international standards to ensure zero defects in product quality.

Diversified Customization and Superior Service

EATHU has a professional engineering team that can provide customized solutions according to customers' needs. Whether it's special materials, non-standard sizes, or requirements for complex working conditions, it can meet them with its rich experience and technological strength. Moreover, it offers considerate full-process services for customers, ranging from pre-sales technical consultations, in-sales progress tracking, to after-sales installation guidance and quality feedback handling, comprehensively safeguarding customers' rights and interests. With its advanced manufacturing processes, stringent quality control, and considerate customized services, EATHU continues to pioneer and innovate in the flange industry, winning the recognition and trust of global customers and leading the development trend of the industry.